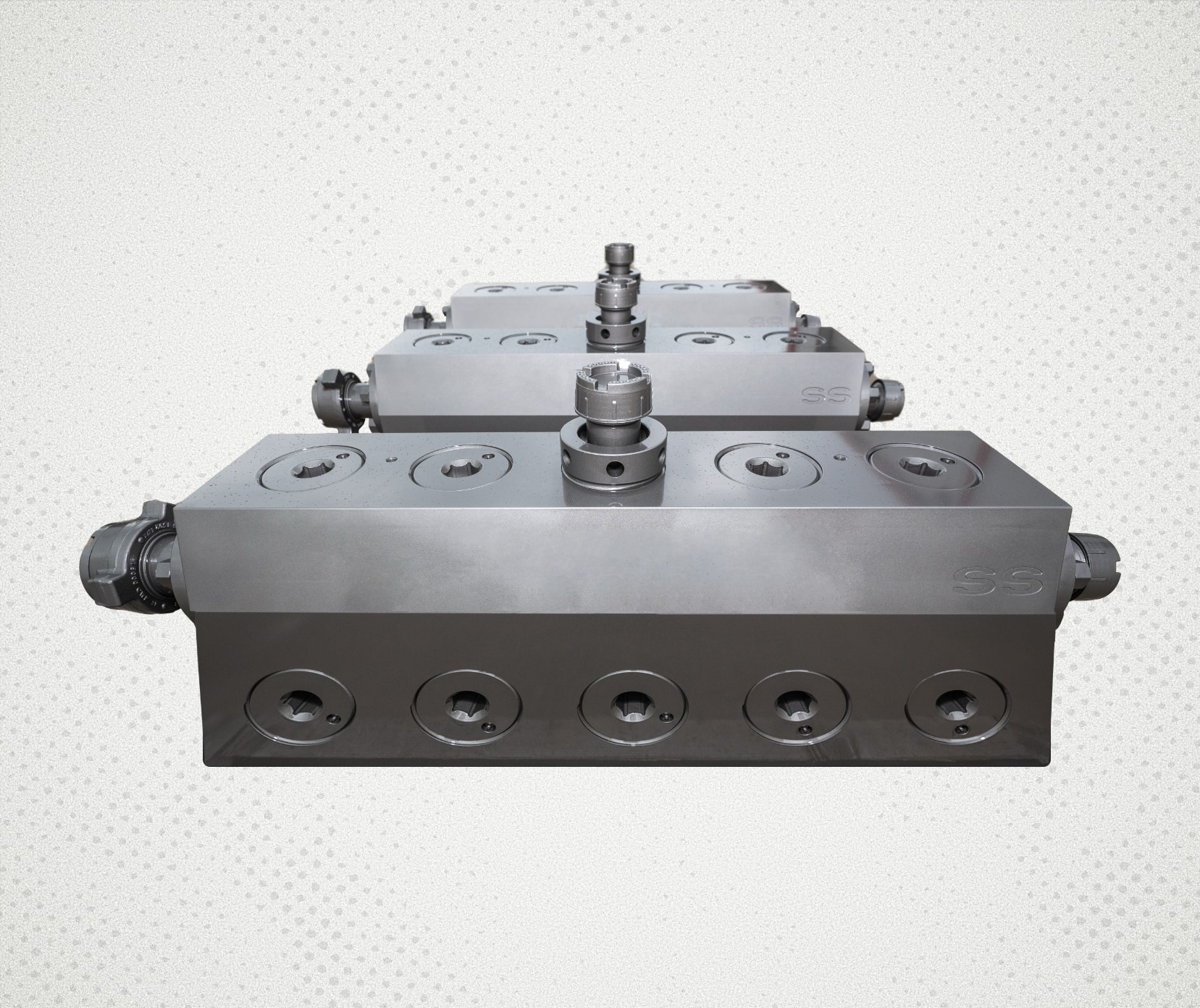

H1 – FLUID ENDS

Built to last. Designed to perform.

The H1 Fluid End from VP is built for real-world durability in high-pressure frac conditions. Machined from 15-5 PH stainless steel and outfitted with heat-treated 4340 alloy discharge flanges, this fluid end is engineered to take a beating—and keep going. Internal flow paths are optimized to reduce stress cracking and turbulence, while precision Garlock packing extends wear life without damaging the bore. Every unit is autofrettaged, pressure tested, and assembled in Alice, Texas. No shortcuts. No compromises. Just American-made performance you can count on.

Key Features

- 15-5 PH stainless steel

Built for corrosion resistance and long service life. - 4340 heat-treated steel flanges

Delivers rugged strength where it matters most. - Optimized internal radii

Reduces stress concentration and cracking in critical areas. - Garlock-style packing system

Extends wear life without chewing up your bore or plunger. - Greaseable Retainer Nuts

Designed to eliminate seizing and ease the removal process. - Autofrettaged, pressure tested, and built in Alice, TX

Made in the USA. Field-ready straight from the shop. - Available in TWS 2250 Triplex